deployable 3D furniture by computer-controlled sewing machine

Researchers enable flat fabric to change into deployable 3D furniture using cords, magnets, and a computer-controlled sewing machine. The team from the Human Computer Interaction Institute (HCII) and Robotics Institute (RI) at Carnegie Mellon University initiates the project, led by the School of Design undergraduate student, Sapna Tayal. There’s a feel of origami around these shape-shifting 3D furniture pieces produced by a computer-controlled sewing machine. The stitches are visible around these modular chairs, tables, and more.

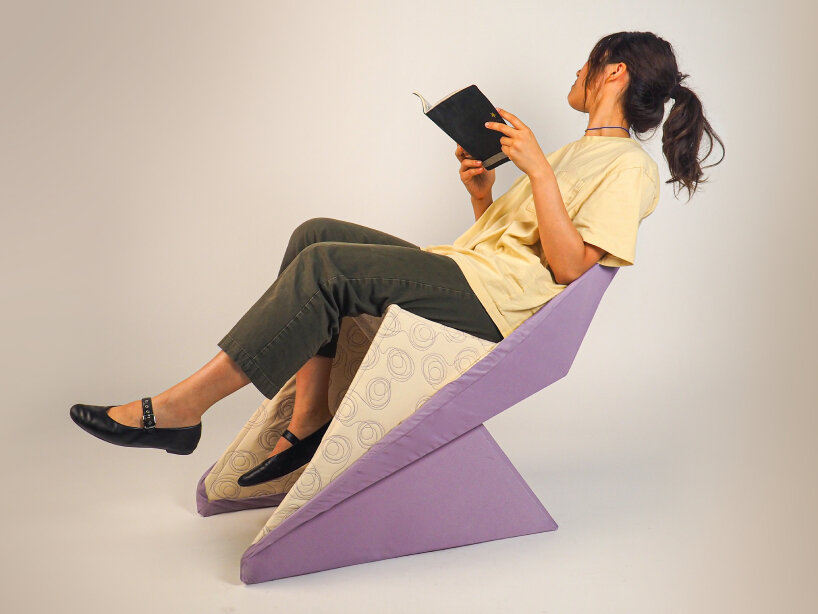

As soon as the user pulls the cord or folds the objects into a form, the real pieces of furniture come to life. It all starts with the idea of ‘flat-to-shape’ objects that can transform into 3D shapes by folding, bending, and assembling. There have been models as such in the past, but these designs were mostly small objects or those that were generated with 3D printers and laser cutters. Then, they required more work as they often needed to be manually put together. It was also difficult to scale up sizable items like furniture. What the researchers chip in is building on this idea to create larger and easy-to-deploy 3D furniture using a computer-controlled sewing machine.

all images courtesy of Sapna Tayal, Dr. Lea Albaugh, Dr. Jim McCann, and Dr. Scott Hudson

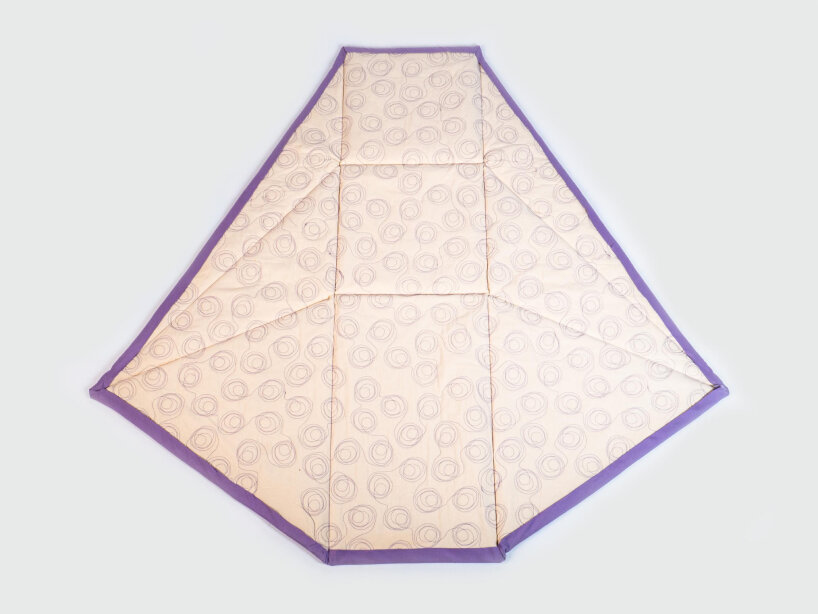

Modular flat fabric with ‘pockets’ for structuring

The researchers – comprising Sapna Tayal, Dr. Lea Albaugh, Dr. Jim McCann, and Dr. Scott Hudson – devise a method to create the deployable 3D furniture generated by the sewing machine. They create pockets between the layers of the fabric. Then, they can insert stiff panels into these pockets, including wood, plastic, or even electronic components. The materials give the objects fabric structure and shape as well as make them robust enough to stand as furniture. The flat fabric then becomes modular, given that it features pockets for shaping materials.

The textile used differs depending on the 3D furniture the sewing machine churns out. The researchers adopt muslin for bigger pieces, while for the smaller and delicate ones like lamps, they use lighter fabrics. They can adjust each panel based on the furniture’s specific function. For example, a chair needs thicker plywood panels to support the user’s weight. Then, for a lamp, a lightweight, see-through fabric tops the surface to let the LED light shine through.

researchers enable flat fabric to change into deployable 3D furniture

cord, magnets, Velcro, or linings for folding and assembly

From being flat to deployable, the 3D furniture made by a computer-controlled sewing machine needs to either have a cord, magnets, Velcro, or just linings for folding. For the chair and bag, the researchers decide on giving them fold lines so users can just assemble them by following their forms. As for the side table, there’s a cord that deploys and shifts it back into a flat piece. ‘The cord acts on short rectangular struts, which meet in the center under the tabletop when fully deployed, stopping further movement,’ says Sapna Tayal.

For the chair, the design researcher says that she glues neodymium magnets into its milled pockets. ‘These allow the chair to snap into place. They also align the panels, while the fabric and panels carry the primary loads,’ she adds. So far, the researchers, primarily Sapna Tayal, have tapped into the design flexibility of a computer-controlled sewing machine to provide deployable 3D furniture. For the design researcher, it is ‘an exciting example of the wide world of reliable and capable fabrication technologies that have been overlooked outside of their niches.’

a computer-controlled sewing machine produces the flat fabric

some of the pieces have cords to ‘snap’ them into place

other objects only have fold linings that users follow to assemble the pieces

there are pockets to insert stiff panels such as wood and plastic to make the pieces functional